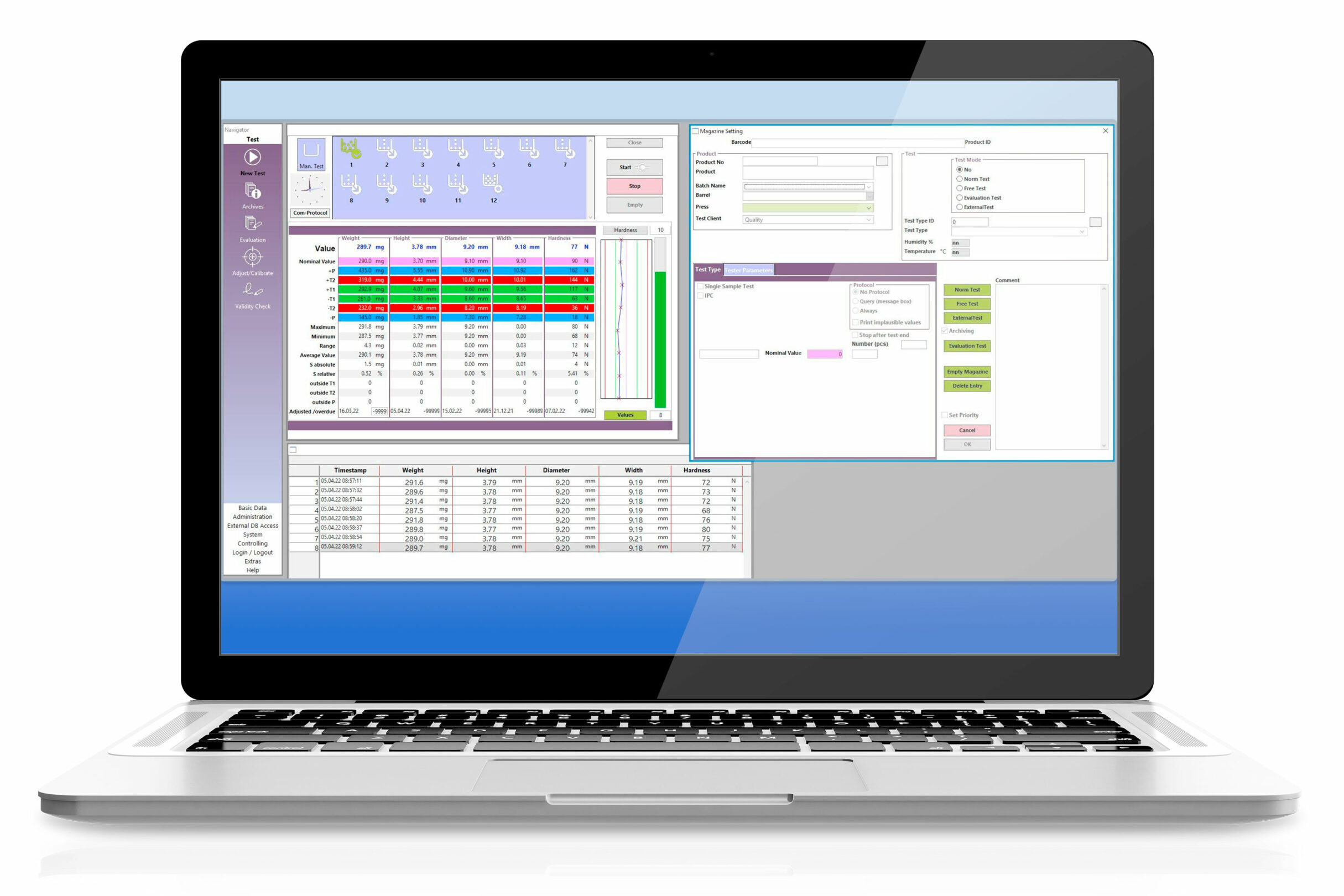

Our powerful TTS11 software is the ideal tool for continually controlling and monitoring your production processes in their entirety.

The most important performance features at a glance:

- SQL database standard: Frontbase (adaptation to other databases possible)

- 21 CFR Part 11 compliant

- Integrated audit trail, regulated access control and access management, documented change control

- Integrated calibration and calibration function as well as monitoring

- Archive manager for administration and output of completed tests

- IPC quality controls

- Automatic identification of the test machine by the software system

- Evaluation manager with versatile possibilities of evaluating measurement results, products, batches, containers, individual tests

- Selection of evaluation parameters and variable limit values

- Batch management

- Test execution according to DAB/USP or proprietary specifications

- Alarm function and management for documenting incidents during test execution

- Conversion functions for different measurement units

- Tolerance bands relative or absolute

- Dynamic calibration by means of external measuring device

- CSV export

- ODBC interface for reading out internal internal data · Electronic signature with automatic PDF filing · Product selection via barcode

- Automatic test execution of several defined tests (12-station feeder)

- Integrated form manager for user customized reports

- Flexible language customization / field naming

- Support of all test systems by Kraemer Elektronik GmbH

OPTIONAL

- Software also available as analysis software without device control functionality

- Controlled database read access via ODBC interface

- Connection to central data management and process control system, integrated transfer of master data, transmission of test parameters, etc.

- E-documents, test protocols and analysis data as PDF files, authorization via electronic signature

Thought-out and powerful: functions of the TTS11 software (selection)

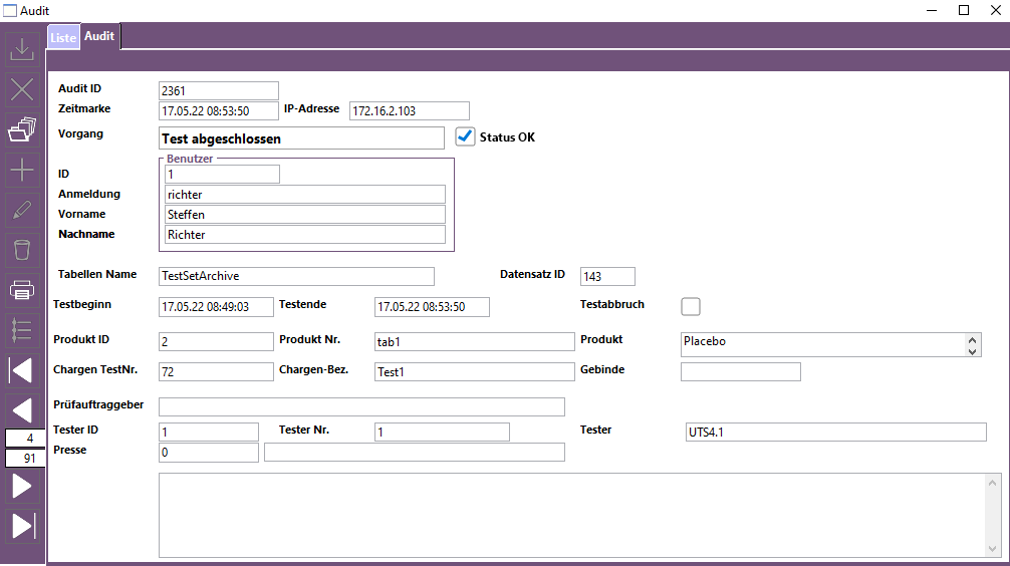

Integrated audit trail

All events or changes occurring in the system are clearly displayed in the audit.

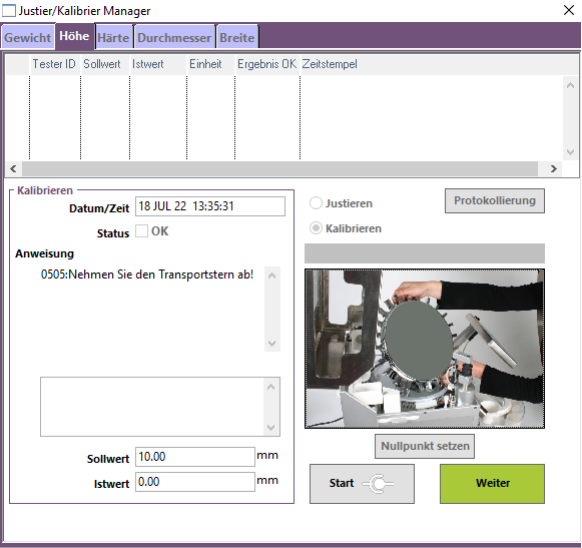

Adjust, calibrate, monitor

The integrated adjustment/calibration function makes it easy to adjust or calibrate the devices. All procedures are described and, if necessary, illustrated with pictures. The integrated monitoring function informs the user when the next calibration is due.

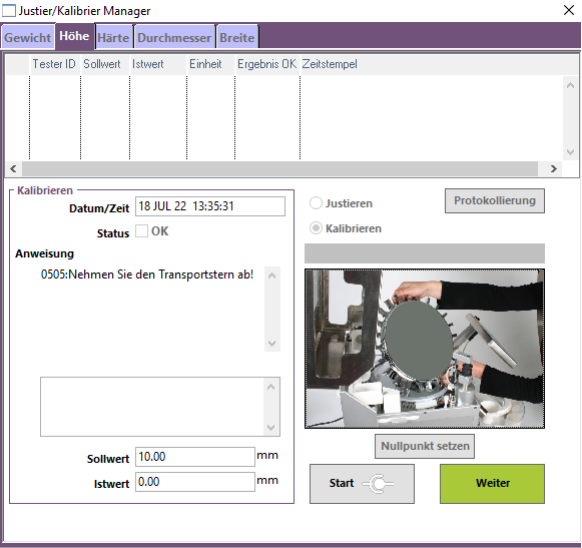

Adjust, calibrate, monitor

The integrated adjustment/calibration function makes it easy to adjust or calibrate the devices. All procedures are described and, if necessary, illustrated with pictures. The integrated monitoring function informs the user when the next calibration is due.

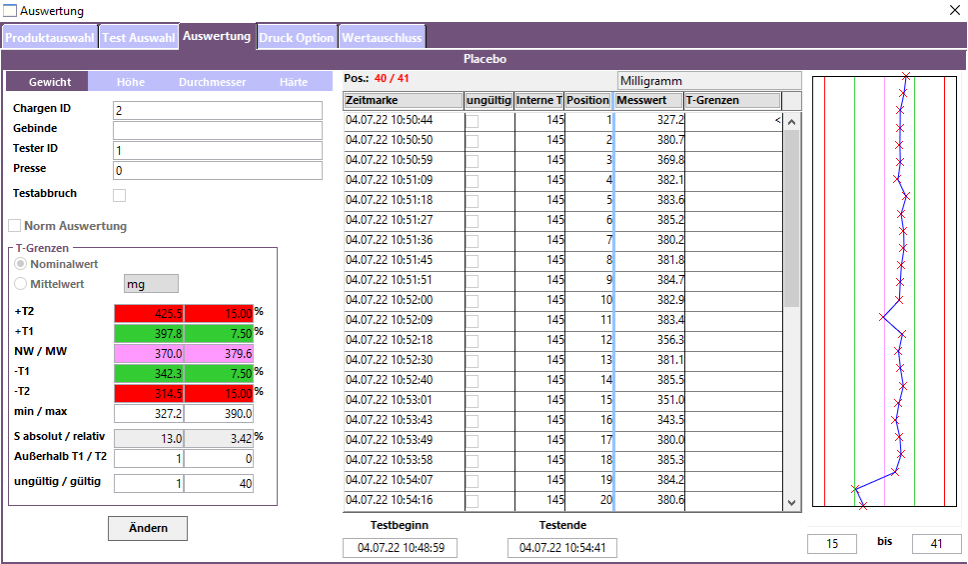

Evaluation of measurement results, products, batches, containers and individual tests

The versatile evaluation manager can be used to quickly create evaluations of multiple tests, batches, tablet presses or clients. The evaluations can be printed or electronically signed, if required.

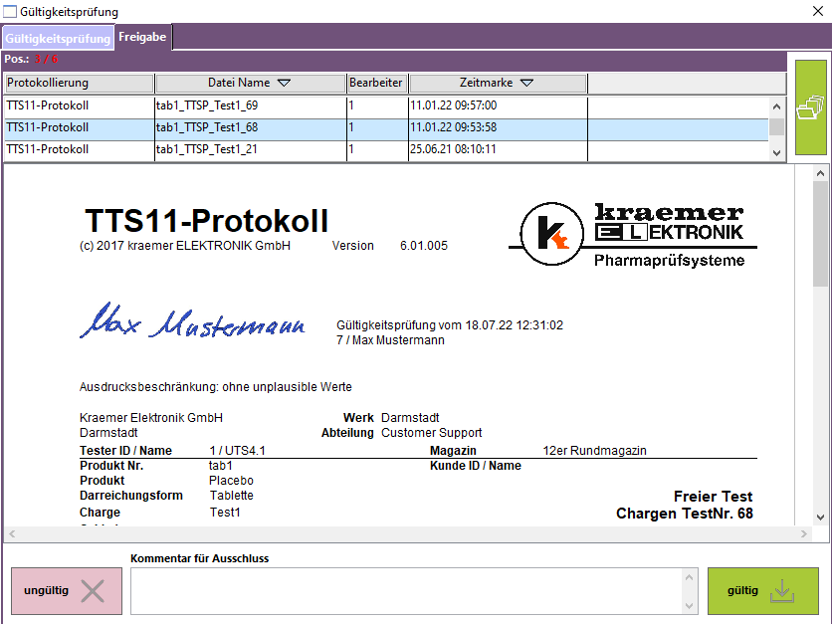

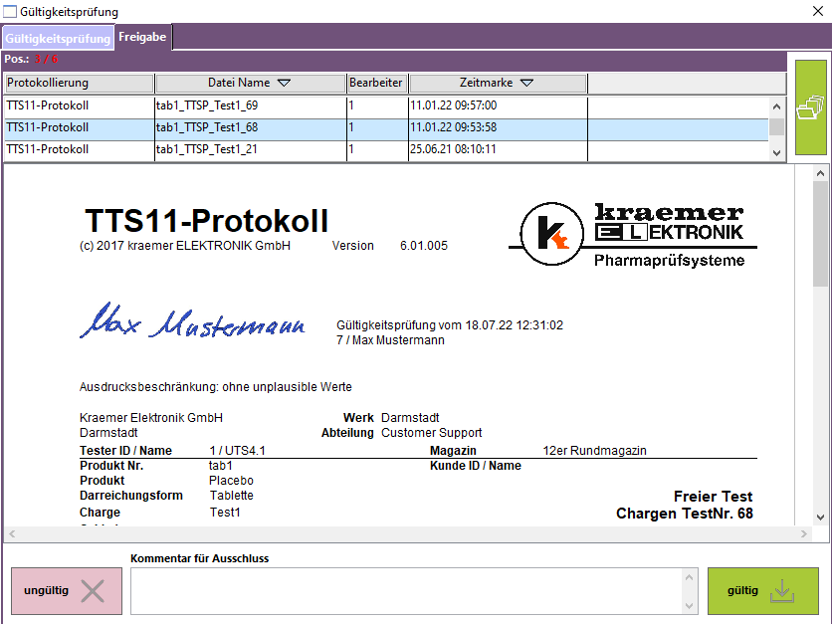

Electronic signature with automatic PDF filing

Executed tests can be digitally signed via the software. Up to 2 signatures (validity and release) can be generated. After completing the process, a PDF file is automatically generated and saved to a preconfigured location.

Electronic signature with automatic PDF filing

Executed tests can be digitally signed via the software. Up to 2 signatures (validity and release) can be generated. After completing the process, a PDF file is automatically generated and saved to a preconfigured location.

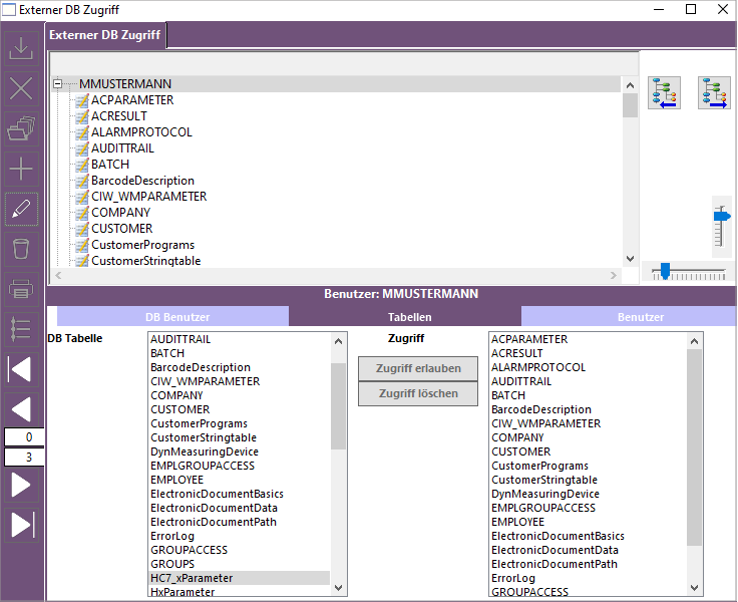

ODBC interface for reading out internal data

An ODBC access can be configured for collecting test data in a superordinate system. Different users can be created with individual rights on database tables.

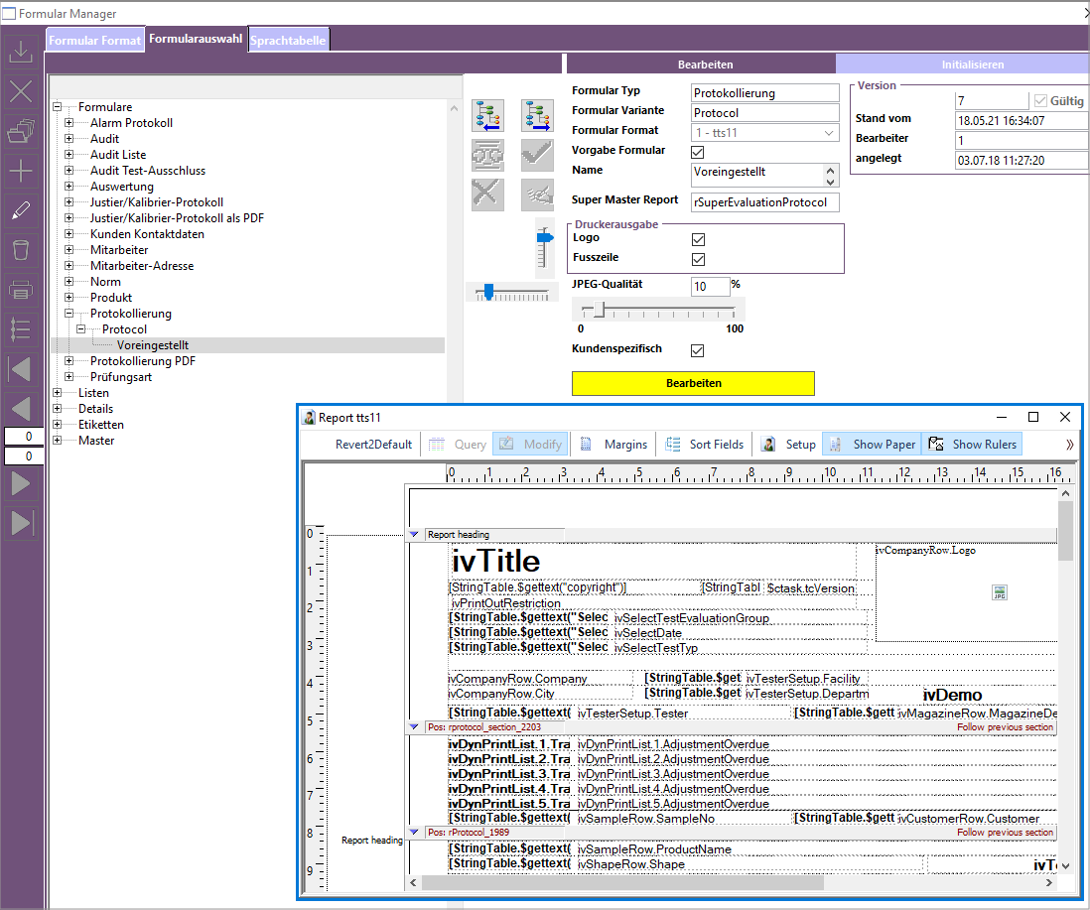

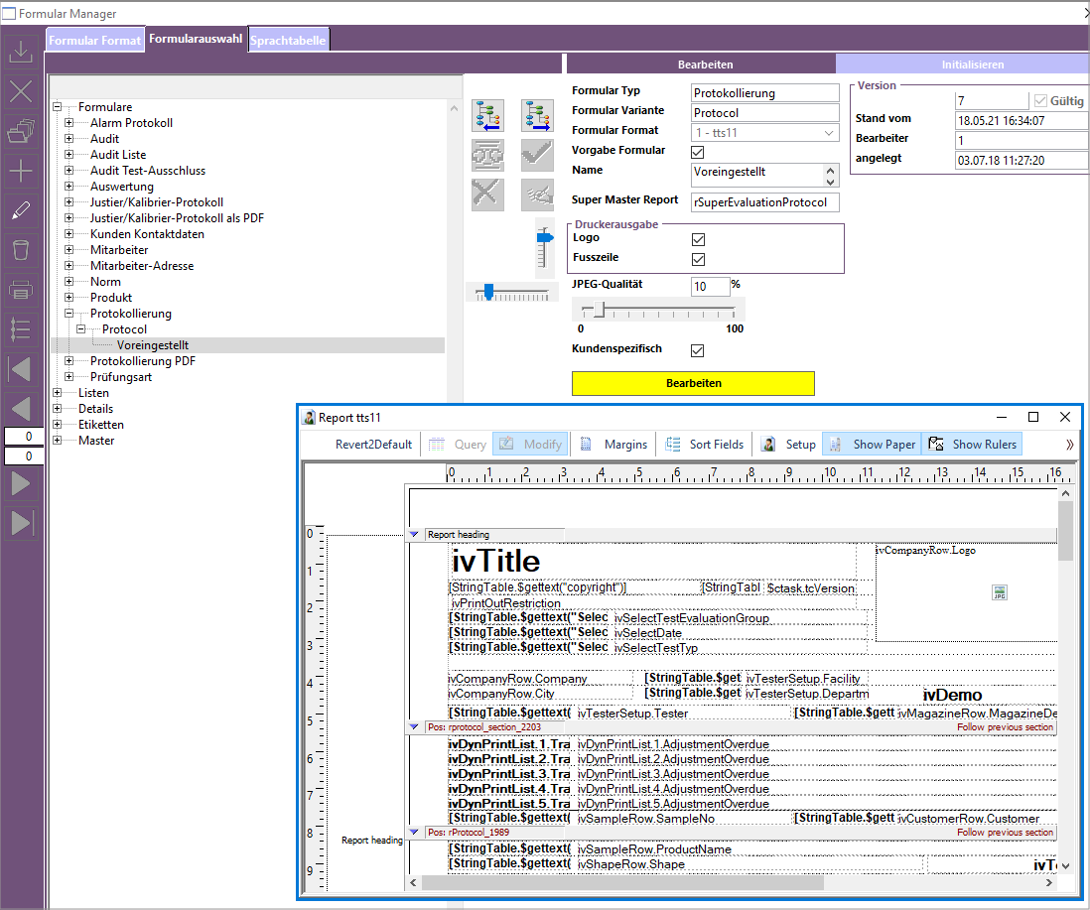

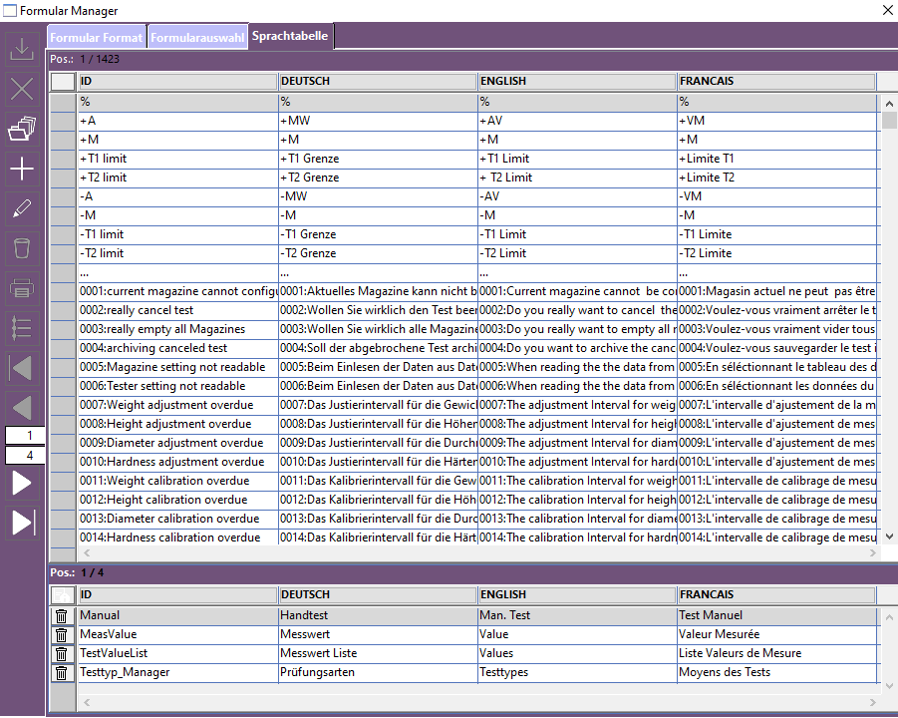

Integrated form manager for user-customized reports

With the integrated form manager, all printouts can be easily customized to meet customer requirements.

Integrated form manager for user-customized reports

With the integrated form manager, all printouts can be easily customized to meet customer requirements.

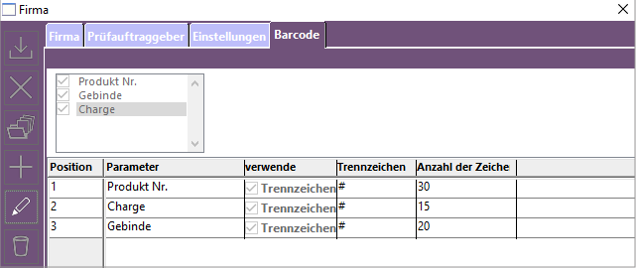

Product selection via barcode

For the process-safe input of data, samples can be read in using a barcode. Based on the data, the test is automatically preconfigured automatically without requiring any further user input. The content of the barcode can be configured in the TTS11.

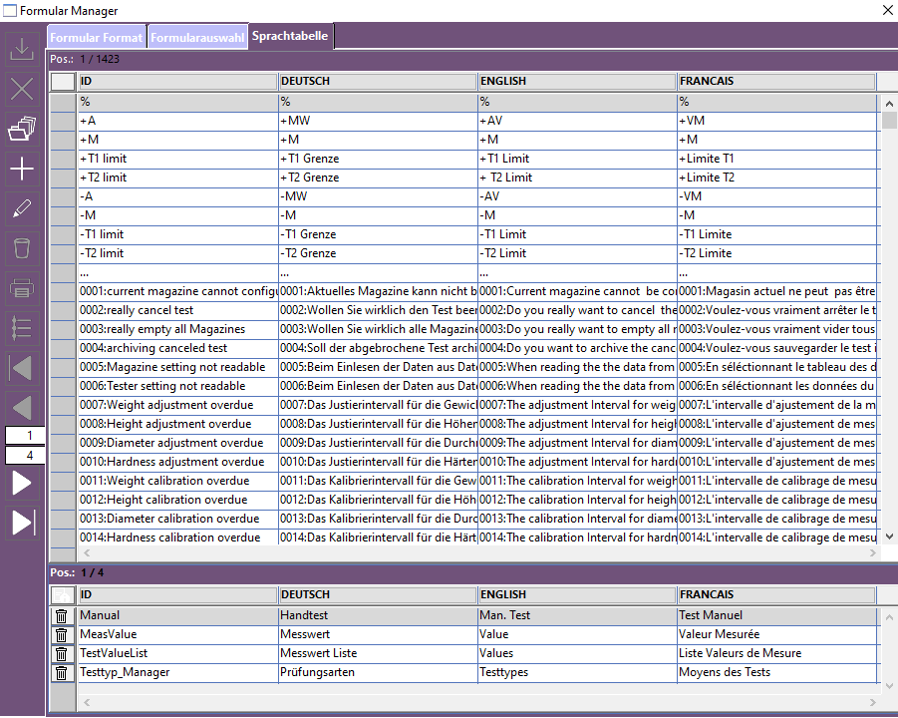

Flexible language adjustment / field naming

All texts within the software can be modified using the editable language table. For instance, you can adapt field names to internal regulations.

Flexible language adjustment / field naming

All texts within the software can be modified using the editable language table. For instance, you can adapt field names to internal regulations.

Dynamic calibration with external measuring device

To carry out a reliable and precise hardness calibration over the complete measuring range, the TTS11 has a dynamic calibration function. Up to 25 points can be set, which are calibrated automatically by the software without operator intervention.

Your Kraemer Elektronik sales in Germany

Do you have any questions about our tablet testing systems?

Would you like us to make you an individual offer, or are you looking for a special solution?

Contact our sales team: